- Product Description

- Specifications

- Related Products

Product Description

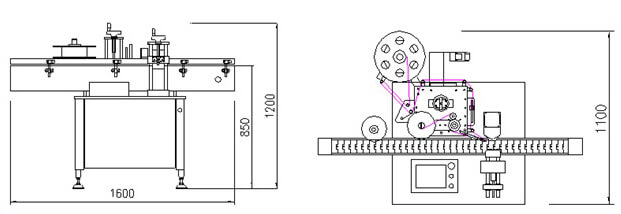

The single-sided label self-adhesive labeling machine is economical, fully functional, easy to operate, and equipped with an automatic teaching programming touch screen. The built-in microchip stores different job settings for quick and easy switching. This automatic labeling system can accurately position labels for cylindrical containers.

Specifications

Technical features of self-adhesive sticker labeling machine series

Easy and precise label positioning

Can label on different bottle shapes (round, conical, triangular)

Applicable to front and back labels on one roll

Labeling speed up to 100BPM

Touch screen control system with job memory

Simple and direct operator control

Full set of protection devices keep operation stable and reliable

On-screen troubleshooting and help menu

Stainless steel frame

Open frame design for easy adjustment and label change

Continuously variable speed motor

Label countdown (for running a set number of labels accurately) to automatic shutoff

Supplied with punch encoding device

Technical Parameter

| No. | Item | Technicial Parameter |

| 1 | Main Material | Stainless Steel 304, Aluminum Alloy 6061 |

| 2 | Dimension | L 2100mm * W 900mm * H 1300mm |

| 3 | Voltage | 220V/50Hz |

| 4 | Power | 1200 W |

| 5 | Production Capacity | 4000-6000BPH |

| 6 | Labeling Accuracy | +/- 1mm beak edge |

| 7 | Label Roll Core | 76 mm |

| 8 | Label Roll Diameter | 350 mm |

| 9 | Label Width | 10~110 mm (special size can be customized) |

| 10 | Label Length | 20~360 mm (special size can be customized) |

| 11 | Bottle Diameter | 30~90 mm (special size can be customized) |

| 12 | Bottle Height | 30~200 mm (special size can be customized) |

About Suzhou Yaoshi Machinery Co., Ltd.'s factory

After Sales Service

1. Installation and commissioning: We will arrange experienced technicians to carry out commissioning and trial production, and at the same time make the equipment reach the rated production capacity of the production line.

2. Training: Our company provides technical training for customers. The training content includes equipment structure and maintenance, equipment control and operation. After the training, the buyer’s technicians can master the operation and maintenance, can adjust the process and deal with various faults.

3. We can send you a video of the machine running. You are welcome to visit our factory and see the machine running. Third-party testing agencies are also accepted for inspection.

4. We can design the machine according to your requirements, and at the same time we will give you our professional advice, as you know, we have been in this industry for 30+ years.

5. Well-trained and experienced staff will answer all your inquiries in English and Chinese

6. 12-month warranty and lifetime technical support.

7. Provide good after-sales service, if you have any questions, please contact us. Provide after-sales service, if you have any questions, please contact us.