- Product Description

- Specifications

- More Details

- Related Products

Product Description

Suzhou Yaos machine's DXGF machine is mainly used for carbonated soft drinks filling and soda water drinks filling and sparkling water filling . It combines rinsing and filling and capping as one automatic body suitable for PET or other plastic bottles. The iso-pressure (iso-barometric) filling technology is adopted enabling it to fill more efficiently and more stably with more output than the machine of the same level from others.

Specifications

Working Principles of soft drink filling machines

The carbonated beverage filling machine is self-designed and manufactured according to the principle of equal pressure filling, which can fill liquid into the bottle washing machine sent by the bottle washing machine.

The filling valve adopts an equal pressure mechanical valve, the filling is fast and sensitive, and the filling level has high accuracy. The centering guide adopts guide rod centering and unique bottle mouth clamping technology, which can ensure the accurate sealing between the bottle mouth and the filling valve and reduce the leakage of materials from the bottle mouth. The main transmission adopts gear transmission, that is, open combined transmission, which has high efficiency, low noise, long service life, convenient maintenance and sufficient lubrication. The frequency converter is used to control the speed of the main motor of the machine, and the machine adopts stepless frequency conversion control. The bottle guide system has a simple structure and can be quickly and easily replaced according to the bottle type.

The whole machine adopts a bottleneck structure for transportation. The whole machine is automatically controlled by PLC, and online display of bottle jams, missing bottle caps and other faults. The material in the filling tank is automatically controlled, and the liquid level sensor detects the height of the liquid level to ensure a stable liquid level and reliable filling.

Technical Parameter

| PROJECT CARBONATED DRINK FILLING MACHINE | |||||||

| Model | DXGF14-12-4 | DXGF18-18-6 | DXGF24-24-8 | DXGF32-32-10 | DXGF40-40-12 | DXGF50-50-15 | DXGF80-80-20 |

| Capacity (BPH) | 2000-3000 | 3000-5000 | 5000-7000 | 7000-10000 | 10000-15000 | 16000-20000 | 28000-30000 |

| Applicable bottle | φ=50-115 H=160-330 (200ML TO 2000ML) plastic screw cup or crown cap | ||||||

| Air press(Mpa) | ≤0.4 | ||||||

| Power supply | 4.4 KW | 5.2 KW | 6.2 KW | 6.2 KW | 7.5 KW | 11 KW | 15KW |

| Overall dimension | 2250×1650×2250 | 2600×1965×2250 | 2980×2200×2250 | 3880×2200×2250 | 4000×2250×2500 | 5500×3500×2500 | 8000*2250*2500 |

| Weight (KG) | 2500 | 3500 | 4500 | 6000 | 7200 | 10000 | 11000kg |

Main Features of soft drink filling machine

1. It is adopted that direct connection between air conveyor and inlet starwheel instead of screw and conveyor chains, which is easier for bottle changing.

2. There is no need to adjust the height of equipment through the neck holding tech for bottle transportation. And what is only to change some spare parts.

3. By 3-in-1 monoblock, the bottle goes through rinsing, filling, and capping with little abrasion, and the transferring is stable, bottle changing is easier.

4. High-speed filling line is clamp transferring technology. Bottle shapes are more varied, and the working table inside the machine is more laconic.

5. Especially designed stainless steel bottle clamp does not contact the thread parts of the bottleneck, avoiding the second contamination.

6. High speed and large flow filling valve assure the high filling speed and exact fluid level.

7. Parts in contact with the liquid are all of excellent stainless steel or food level plastic. The electric system is of international brand and achieves the national food sanitary standard.

8. The bottle-out starwheel is of screw down shape. When bottle size is changed, there is no need to adjust the transferring chain’s height

Main configuration

| No | Name | Brand |

| 1 | Motor | China |

| 2 | Motor in cap sorter | China |

| 3 | Rinsing pump | Nanfang, Hangzhou |

| 4 | Magnetic valve | Airtac, Taiwan |

| 5 | Cylinder | Airtac, Taiwan |

| 6 | Air parts | Airtac, Taiwan |

| 7 | Frequency convertor | Siemens |

| 8 | Transformer | China |

| 9 | Photoelectric switch | AUTONICKS |

| 10 | Proximity switch | AUTONICKS |

| 11 | PLC | Siemens |

| 12 | Touch screen | Siemens |

| 13 | Pnuemtic parts | Airtac, Taiwan |

| 14 | AC contactor | Schneider |

| 15 | Microrelay | Schneider |

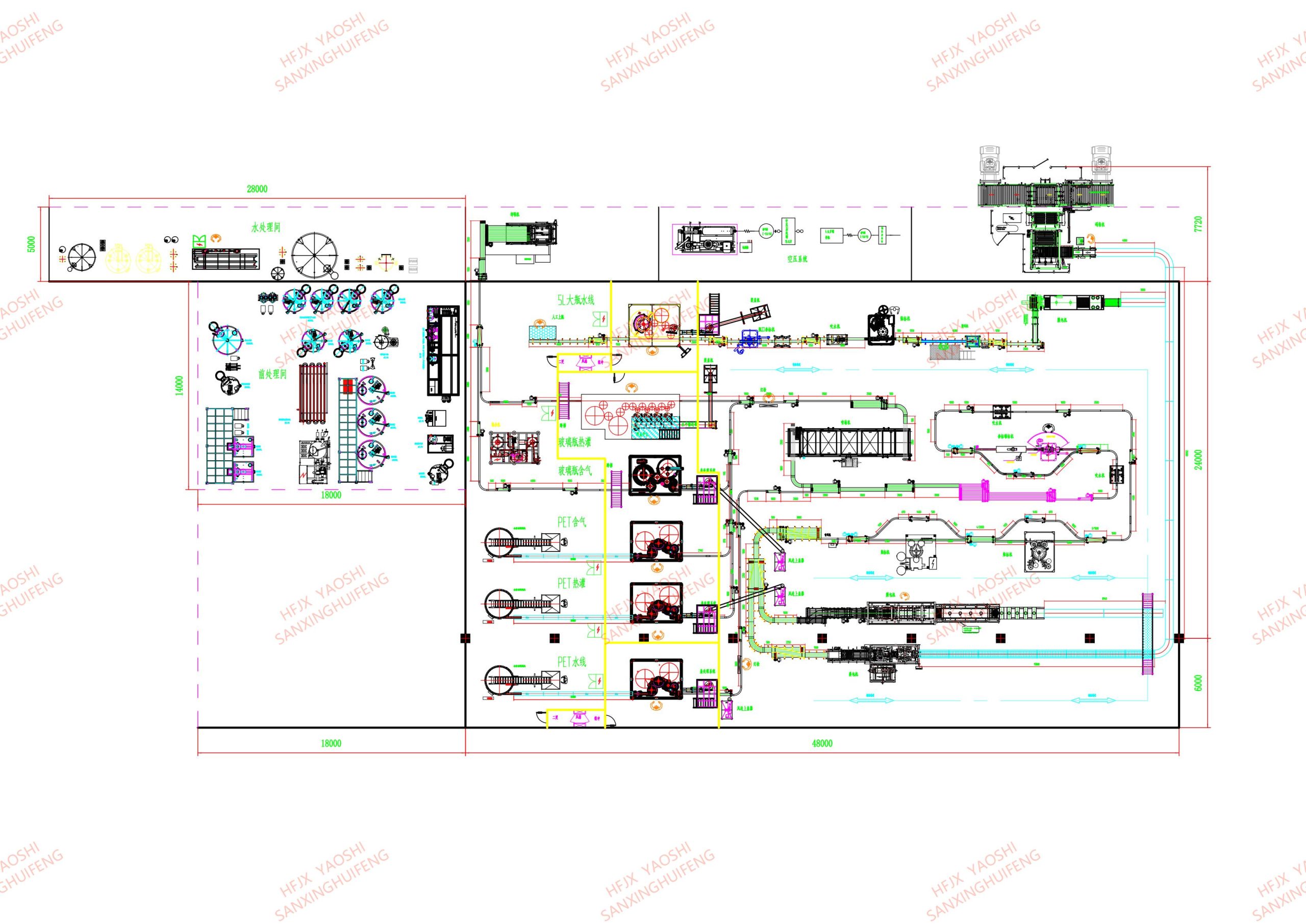

Flow chart (bottling production line)

A) Bottling production line

PET granules – injection molding machine – blow molding machine – PET bottles

B) Water treatment system

Raw water – water pump – quartz sand filter – activated carbon filter – water softener – reverse osmosis – UV sterilizer – ozone generator – finished product water tank

C) Pretreatment system

White sugar – sugar melting pot – syrup mixer – blending tank – carbon dioxide CO2 mixer

D) Filling and packaging part

Blow molding machine/unscrambler – air conveyor – washing, filling and sealing three-in-one machine – conveyor belt – bottle warming tunnel – dryer – date coding machine – labeling machine – packaging machine – finished product

About Suzhou Yaoshi Machinery Co., Ltd.'s factory

After Sales Service

1. Installation and commissioning: We will arrange experienced technicians to carry out commissioning and trial production, and at the same time make the equipment reach the rated production capacity of the production line.

2. Training: Our company provides technical training for customers. The training content includes equipment structure and maintenance, equipment control and operation. After the training, the buyer’s technicians can master the operation and maintenance, can adjust the process and deal with various faults.

3. We can send you a video of the machine running. You are welcome to visit our factory and see the machine running. Third-party testing agencies are also accepted for inspection.

4. We can design the machine according to your requirements, and at the same time we will give you our professional advice, as you know, we have been in this industry for 30+ years.

5. Well-trained and experienced staff will answer all your inquiries in English and Chinese

6. 12-month warranty and lifetime technical support.

7. Provide good after-sales service, if you have any questions, please contact us. Provide after-sales service, if you have any questions, please contact us.